New models predict the properties of 3D print onto textiles

2020-12-14

Three years ago, Prisca Eutionnat-Diffo began her doctoral studies in the international doctoral programme SMDTex (Sustainable Management and Design for Textiles). She had been working as an Research and Technology Engineer at Autoneum in the UK, one of the world's leading manufacturers in vehicle acoustics and thermal insulation. Her research focused mainly on developing the textiles used inside cars.

“I made the choice to become a textile engineer because first, I am a passionate scientist, and textiles is a more concrete scientific area. Textiles are found everywhere; therefore, being a textile engineer could also open many doors in industry,” says Prisca Eutionnat-Diffo.

Wide range of uses

The types of textiles she has worked with are functional and technical. It is thus the function, not the aesthetics, that is in focus. An example is protective gloves, the main function of which is to protect the wearer from cutting themselves. Technical and functional textiles have a wide range of uses in a variety of industries, such as agriculture, healthcare, and the automotive industry.

Prisca Eutionnat-Diffo had long ago considered pursuing a doctorate because she wanted to be specialized in a specific and exciting subject. By chance, a colleague told her about the SMDTex programme. But she almost missed the opportunity.

“I was told about SMDTex just three days before the application deadline. I am really grateful to my friend and colleague,” says Prisca Eutionnat-Diffo.

Challenges to maintain quality

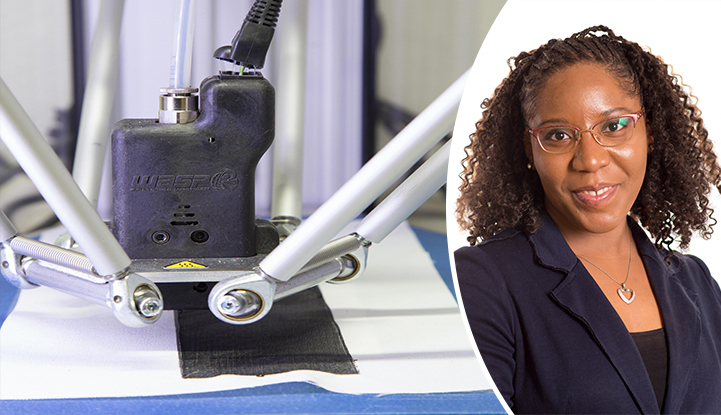

As a textile engineer, she is interested in the emergence of functional textiles and techniques such as 3D printing. This also became the subject of her dissertation, 3D printing of polymers onto textiles: An innovative approach to develop functional textiles.

With 3D printing of polymers onto PET textile materials, it is possible to integrate sensors onto the surface of the textiles. For example, sensors that can measure heart rate or temperature. She chose to take a closer look at FDM, Fused Deposition Modeling, which is a well-known technology in 3D printing. Compared to existing conventional methods, it has advantages such as resource and cost efficiency, it generates little waste, and it is suitable for tailor-made production. Using it to apply functional layers of polymers to textiles, however, is new. The challenge with the technique is to maintain the quality of the fabric when it comes to bending, flexibility, tensile, and abrasion.

Through experiments and statistical modeling, Prisca Eutionnat-Diffo shows how the textiles will be affected by 3D printing using FDM technology. In addition, she has shown how different compositions of thermoplastic polymers and elastomers, when used and printed on the fabric in a certain way, make the textile material retain its flexibility. Adhesive properties could also be improved by functionalising the surface of the fabric and by adding adhesives.

“In the short term, my findings can be helpful for researchers working in the field. In the long term, my work, combined with additional research, will be particularly helpful for academia and industry in the development of functional textiles,” says Prisca Eutionnat-Diffo.

Fantastic and challenging years

She describes her three years as a doctoral student in SMDTex, during which the doctoral students have worked in Sweden, France, and China, as both fantastic and challenging. Admittedly, the coronavirus pandemic prevented her from making one last visit to China and working on some remaining experiments that would have been carried out in France. However, they were not part of her doctoral thesis, and on the whole, her thesis was affected very little by the pandemic.

On 1 December, she defended her doctoral thesis in Textile Materials Engineering at the University of Borås. For a couple of months now, she has been working at Autins in the UK, one of the leader in acoustics and filtration providing solutions for vehicles and office furnishings.

“I am very happy, relieved, and satisfied to have completed my thesis.

I have been dreaming of this day for years and sometimes I still do not realize I have completed it. I really would like to thank once more the European Commission, my very nice and professional supervisors from the three universities (University of Boras, ENSAIT, and Soochow University) based in Sweden, France, and China, my colleagues, the companies I collaborated with, my friends and relatives for their continuous support.”

Read more

Doctoral dissertation 3D printing of polymers onto textiles: An innovative approach to develop functional textiles