New research: How Swedish hemp can become a technical textile

2022-10-18

Finola industrial hemp is grown in Sweden for its seeds, which are used for animal feed and pressed into oil. Most of the plant is not used at all, but rather is left in the field or thrown away. It's a waste of natural resources, noted May Kahoush, one of the researchers working to find new ways to use hemp fibres.

“As engineers, we see a problem and we want to solve it. This is an opportunity to harness a natural resource while reducing the textile industry's dependence on fossil fuels. Many textiles today are made from oil. Materials like cotton, on the other hand, require huge amounts of water and chemicals," said May Kahoush.

Processed without harmful chemicals

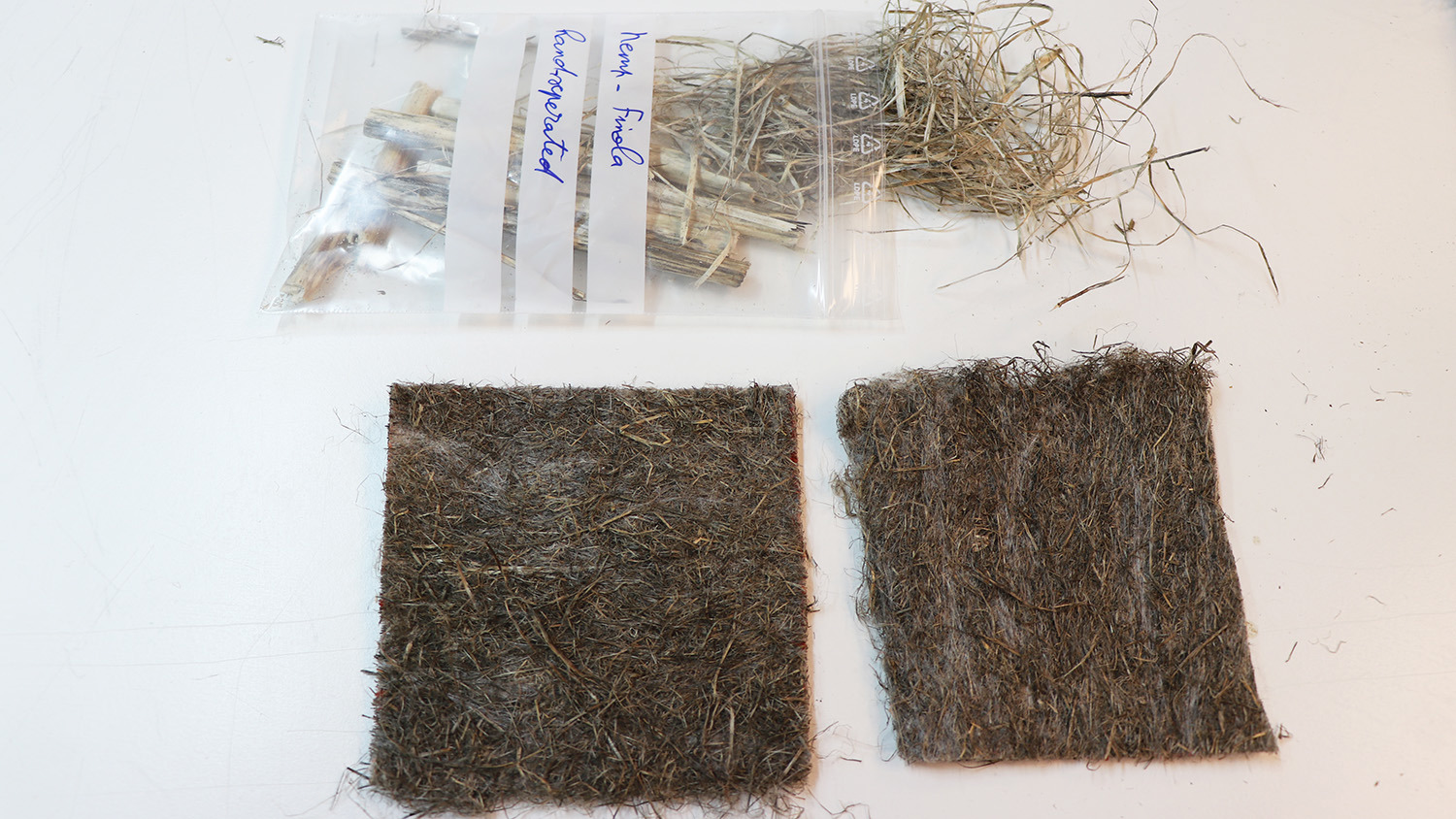

On a table in a lab at the Swedish School of Textiles, she has laid out hemp fibres in various stages as well as early prototypes of a so-called nonwoven* textile. Making a light cracking sound, she breaks open a dry hemp stalk and pulls apart the long, fringed bast fibres that lie around the hard kernel.

“These fibres don't look very nice, but they can be processed and softened without using harmful chemicals. The woody core of hemp could be used for bioplastics and composites,” said May Kahoush.

The project is led by Nawar Kadi, Professor of Textile Technology at the University of Borås. The project is run together with Science Park Borås, which is part of the university. Key players from different parts of the value chain, such as Swedish Hemp Industries, are also involved.

Treated with ultrasound

She notes that the raw fibres need a "makeover" and shows that can be done. With ultrasound, the fibres are stripped of unwanted parts, and by carding the fibres, they are separated and brushed. The domesticated fibres are then mixed with a bio-composite and pass through a needle punch. As the textile is fed through the machine, the steady beat of the needles transforms the material into what feels like a felted carpet.

“Now the material is much softer and more durable," said May Kahoush. “We're still early in the process, but we think this hemp textile could be used for different types of sound and heat insulation, for example as an environmentally friendly alternative to fibreglass. Another idea is the automotive industry, a huge sector that is heavily dependent on oil. They are asking more and more for materials that can be recycled.”

Finola hemp grows like a weed

May Kahoush compares hemp, and in particular the Finola hemp grown in our neighbourhood, to a weed. It grows and thrives without requiring irrigation or pesticides. This makes it environmentally sustainable. Under certain circumstances, hemp can even store more carbon dioxide than trees.

About the project

The project Bio-based residual streams with potential in technical textile industry is being carried out in collaboration with the University of Borås and Science Park Borås in collaboration with the Swedish Hemp Industries, OrganoClick, House of Hemp, Ekolution, Borgstena, Svenska Naturtak, and Sporda. The project is being funded by Vinnova and will run from 1 November 2021 to 31 October 2024.

Nawar Kadi, project leader

May Kahoush researcher's profile page

* Nonwoven refers to different types of materials that are neither woven nor knitted. Instead, the fibres are in no particular order; fibreglass is an example.

Lina Färm

Lina Färm